Boost Food Safety with Hygienic Poultry Packaging Solutions

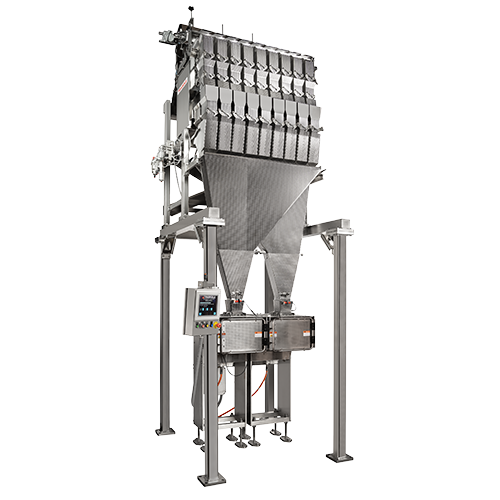

Safely Package Fresh Poultry with Integrated Weighing and Bagging Systems

Triangle belt-fed weighers safely handle your wet, sticky poultry products. Pair one with a Triangle vertical form fill seal bagger for a complete poultry packaging solution. The scale mounts directly over your bagger, meaning there’s no mezzanine required. It’s never been easier to eliminate unnecessary sources of contamination, reduce your overhead costs, save floor space and further enhance your poultry packaging line’s food safety.

Gain Full Access to Large Poultry Products with Zipper Tape Packages

The Delta rotatable jaw bagger features a zipper tape applicator and is designed to form 3-sided seal bags made from low-density polyethylene (LDPE). It allows you to simply package bulky pieces of chicken in easy-access bags that fully open across the entire width of the package. It is designed and built to endure harsh environments and meet the strictest sanitary requirements, with availability in three levels of sanitation, including stainless steel, stainless steel washdown and USDA/3-A. This versatile VFFS bagger can handle various zipper bags, including transverse zipper bags for chicken nuggets, zipper tape bags for frozen chicken, longitudinal zipper bags for RTE poultry products and pre-applied zipper bags for frozen poultry.

Increase Versatility with Rotatable Jaw Baggers

Easily run multiple bag styles on the same VFFS bagger while reducing downtime and enhancing worker safety. Triangle X-Series baggers for poultry offer rotatable jaws which allow traditional pillow bags or 3-sided seal pouches to run on the same machine. A unique sealing jaw carriage rotates in seconds for quick changeovers. Available in 3 levels of sanitation, they are designed to meet the food safety requirements your poultry application demands, including stainless steel, stainless steel washdown and USDA/3A models. X-Series baggers with rotatable jaws are ideal for poultry products such as chicken breasts, nuggets, turkey meatballs and much more.

Handle LDPE Packages with Flexible Bag-in-Box Cartoners

Automate your poultry bag-in-box cartoning while providing greater flexibility, lower maintenance and reduced downtime. Our bag-in-box cartoners easily load one or more packages of poultry products into the same box with single, twin- and triple-pack bag-in-box capability. It is able to load bags made with both laminate and LDPE. Due to their unique design that shoots bags into the box, rather than placing them into the cartons, they are a strong alternative to top-load carton loading. This packaging solution is ideal for IQF bagged products such as slices of poultry, nuggets, stuffed chicken and turkey breasts, popcorn chicken and more.

Easily Load Bowls or Trays of Poultry with a Rotary Wheel

If you need to load poultry into TV dinners or frozen meals, the Triangle rotary wheel is an ideal solution. Designed for tray/clamshell packaging applications, this poultry packaging system loads fresh or frozen poultry into bowls, trays, or partitioned sections at speeds up to 75 trays/minute for a single-wheel poultry packaging system and 150 trays/minute for a dual-wheel. Easily integrate an inline scale with a rotary wheel for an integrated poultry packaging system.