Quickly Handle Large Weighments with Belt-Fed Weighers

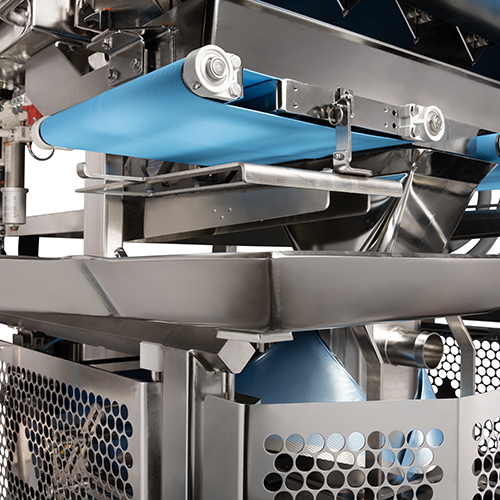

Triangle belt-fed weighers are ideal for larger pieces of difficult-to-run products, such as fresh boneless chicken or cubed, marinated or shredded proteins.

The belt-fed scale is designed with 6” x 6” buckets, and can handle large weights and pieces with ease–up to 10 lbs in one discharge. With 12 selection buckets and a maximum speed of 60 discharges per minute, the Triangle belt-fed weigher offers a maximum weighment per discharge of 200 oz.

Offering unmatched accuracy, our weighers provide a quick return on investment. Customers enjoy immediate savings in product giveaway and our unique belt transfer system does not damage the product in any way, shape or form. Additional savings are realized by fast and easy cleaning and maintenance, with easily removable belts and buckets.

.png)

Streamline Production with Weighers for Sanitary Applications

Combine a Triangle vertical form fill seal bag machine with one of our belt-fed weighers for a complete single-source integrated system. Product flow is an integral component to the success of your food packaging line. Our ability to control that product flow and ultimately get your product into a bag is unmatched. Pair a Triangle VFFS bagger and belt-fed weigher for the industry’s most reliable sanitary integrated food packaging system.

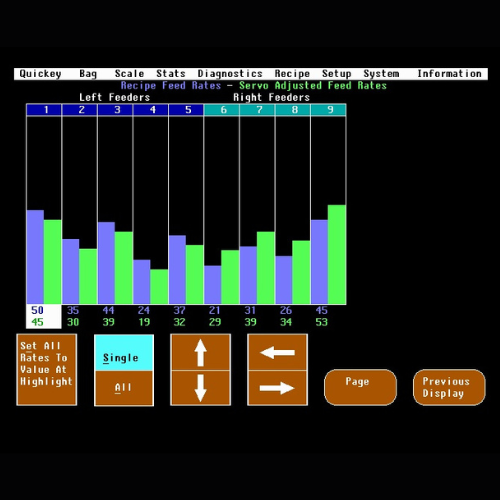

Simplify Operation with Reliable, Non-Proprietary Controls

Non-proprietary controls are user-friendly and easy to maintain. As a Rockwell Automation Preferred Machine Builder Partner, we offer Rockwell ControlLogix, which allows us to offer both the bagger and scale with one control box–an industry first! Reliable and expandable, we offer advanced diagnostics and easy network data acquisition.

Enhance Production with Features that Drive Results

Triangle belt-fed weighers are designed with features that maximize benefits. With a scale mounted directly onto the top of bagger, unqiue vibration resistant weigh cells provide precise weights every time. A product grader lays out and distributes the flow of product onto belt to increase overall accuracy of the package.

Quick-change, tool-less, hand-removable belts, buckets and front trays make changeover and washdown a breeze. Options that further enhance food packaging safety include electropolish smooth, rigid-tex stainless steel or teflon coated contact points (buckets) and sift-proof, sealed bearing bucket doors. Timing gate or rating wheels are also available.

Belt-Fed Weigher Specifications

| Max Speed | Up to 65/min |

| Max Weighment/Discharge | Up to 20 oz |

| PLC | Rockwell |

| Connection | Ethernet |