Enhance Your Food-Safe Production with Triangle Cheese Packaging Solutions

Streamline Cheese Packaging with Sanitary Vertical Form Fill Seal Baggers

Triangle offers the only VFFS bagger and forming tube designed to meet strict USDA and 3-A sanitation standards. This makes Triangle baggers a versatile solution for cheese packaging. Our vertical form fill seal machines offer the advantage of being able to run bags that are up to 5 lbs at over 65 bags per minute while maintaining a hygienic environment.

To further enhance your sanitary packaging, ultrasonic sealing options are available for applications that require hermetic seals.

By significantly reducing the amount of material needed due to the precision welding of the film, ultrasonics also offer material savings. Contributing further savings, they also do not require the use of consumables such as Teflon tape or sealing wax.

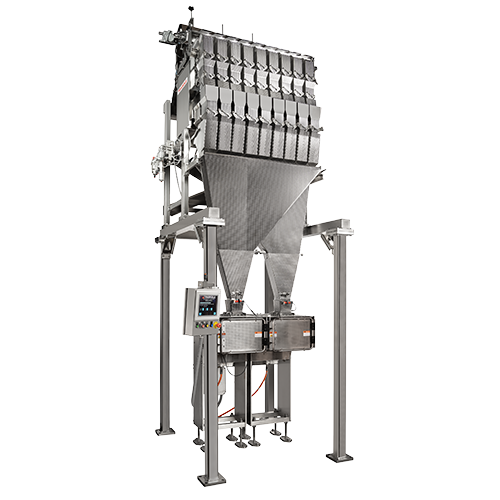

Achieve Weighing Accuracy with Triangle Cheese Scales

Product loss due to inaccurate weighments can be costly. Weighing with unmatched accuracy is possible with a Triangle inline weigher.

Pair a Triangle bagger with a Triangle inline scale or a radial scale from one of our partners for a complete solution that streamlines your cheese packaging operations.

Create a complete cheese packaging solution by adding on a rotary wheel, and all cheese types are able to be loaded into a bowl or tray. A single-wheel tray packaging system can operate at speeds up to 75 trays per minute. Or, up to 150 trays per minute with a dual-wheel tray packaging system.