Versatile Zipper Applicator for Existing VFFS Machines

Our industry-first, a stand-alone integrated transverse zipper applicator, easily converts any brand of existing in-house VFFS bagger to accept 3-flange or 4-flange transverse zippers. It can be easily moved throughout your facility and positioned behind your current VFFS machines. Since it does not replace your existing bagger, training needs are minimized, and usability is simplified. The machine can even be supplied as a mobile unit if necessary.

Field-Proven Zipper Technology

The unit is backed by our extensive experience with zipper packaging, which began in the 1980s when we introduced the industry's first vertical zipper applicator. For decades, Triangle has been the leader in reclosable zipper package technology from standard transverse zipper to 3-side seal longitudinal zipper to zipper tape applicators. Throw in slider zipper technology, half zippers that act as pour spouts and the ability to handle 3 or 4 flange zippers and supported or LDPE films, and it’s easy to see why CPGs have trusted Triangle for reclosable packages.

The flexibility of this stand-alone zipper unit makes it an excellent choice for consumer-packaged goods (CPGs) companies as well as contract packagers. Non-proprietary controls from Allen-Bradley feature a new icon-based, multilingual touch screen HMI to further enhance ease of operation and accessibility. The unit comes standard with a CAT 2 safety rating, with an option for a CAT 3 rating, allowing for peace of mind in operational safety.

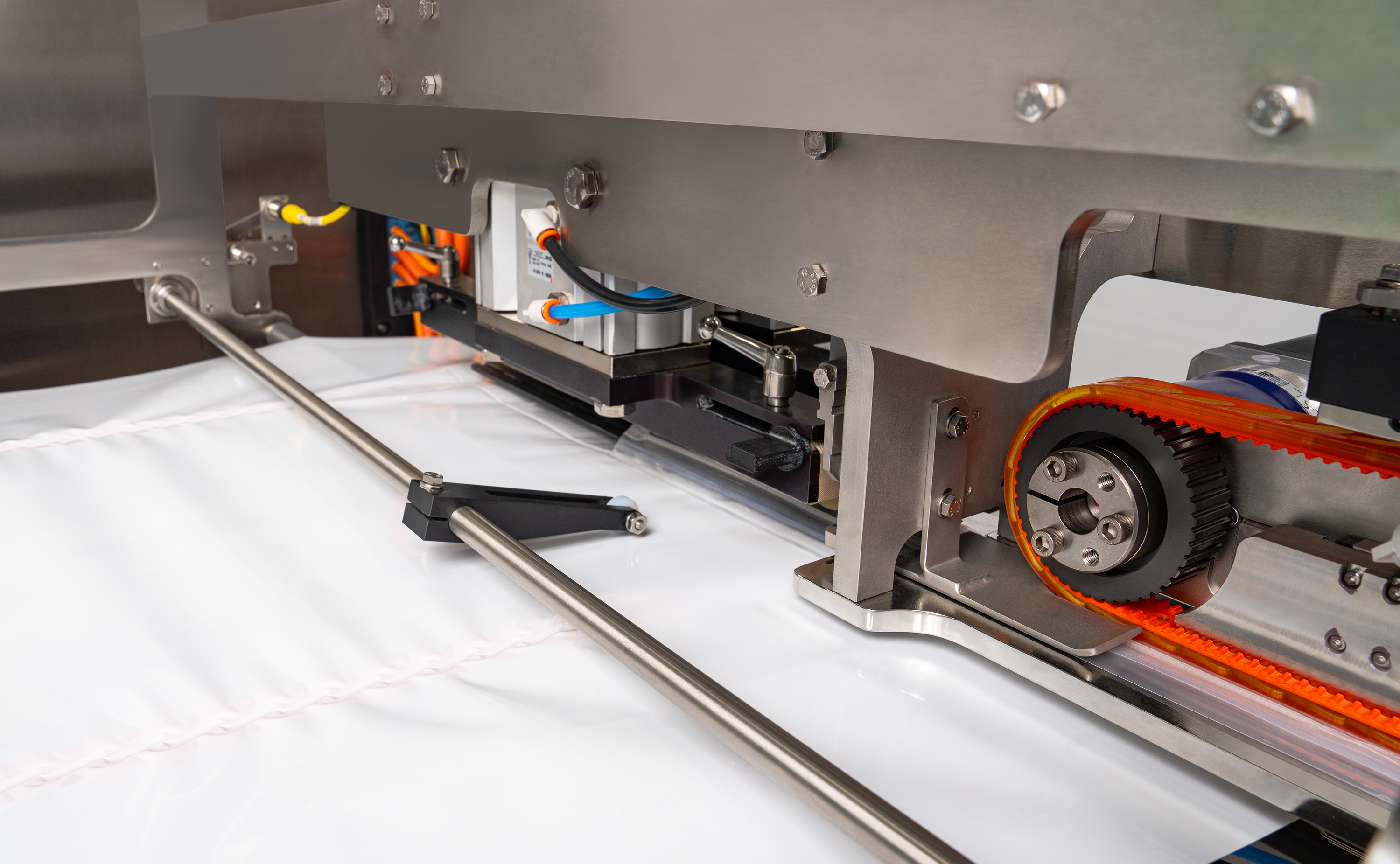

Sanitary Design Improves Food Safety

This zipper unit’s sanitary design makes it ideal for both dry goods and sanitary food applications. Sanitary features of the stand-alone integrated zipper applicator include:

- Stainless steel construction

- A hinged stainless steel NEMA 4X control box

- Heat sealing that prevents contamination

- Sloped surfaces for easy runoff

- Open design with no hidden components